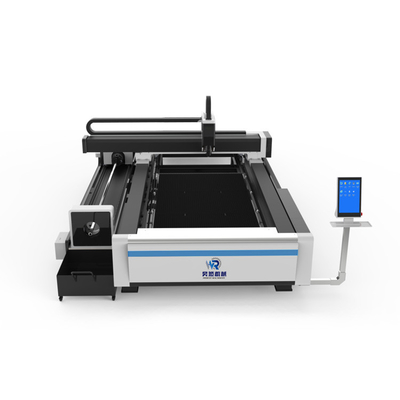

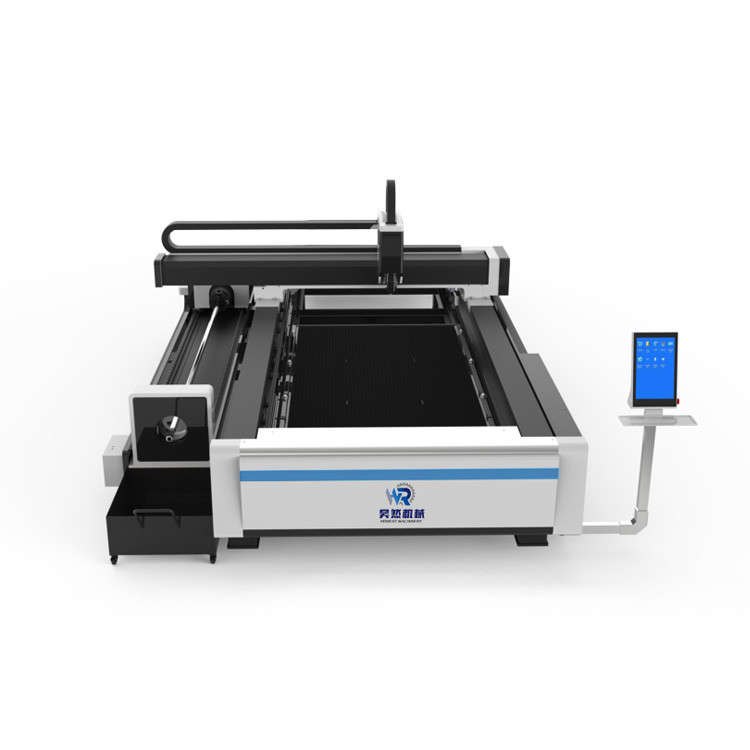

Fiber Metal Laser Engraving Cutting Machines For Plate And Tube Integrated

Product Details:

| Place of Origin: | China |

| Brand Name: | Honest |

| Certification: | CE ISO |

| Model Number: | HN - 1530 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | 20000 USD/ Set-35000 USD / Set |

| Packaging Details: | Wooden Package |

| Delivery Time: | 5-8 Working Days |

| Supply Ability: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

|

Detail Information |

|||

| Application: | LASER CUTTING | Condition: | New |

|---|---|---|---|

| Applicable Material: | Acrylic, Glass, Leather, Metal, Wood | Cutting Area: | 1500mm*3000mm |

| Cooling Mode: | Air Cooling | Laser Source Brand: | RAYCUS |

| High Light: | Integrated Laser Engraving Cutting Machines,110m/min Fiber Laser Engraving Machines,110m/min Laser Engraving Cutting Machines |

||

Product Description

Plate And Tube Integrated Fiber Metal Laser Engraving Cutting Machines

The advantages of fiber laser cutting machine:

2. High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption,it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy operations: fiber line transmission, no adjustment of optical path.

|

Feature/Model

|

HN3015

|

HN4015

|

HN4020

|

|

Working Area (L*W))

|

3000mm*1500mm

|

4000mm*1500mm

|

4000mm*2000mm

|

|

Stroke (X/ Y/ Z Axis)

|

1525mm/3025mm/150mm

|

1525mm/4025mm/150mm

|

2025mm/4025mm/150mm

|

|

X/Y Axis Positioning Accuracy

|

±0.03mm/m

|

±0.03mm/m

|

±0.03mm/m

|

|

X/Y Axis Repositioning Accuracy

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

|

Max. Moving Speed

|

110m/min

|

110m/min

|

110m/min

|

|

Max. Acc. Speed

|

1.0G

|

1.0G

|

1.0G

|

|

Power Porection Grade

|

IP54

|

IP54

|

IP54

|

|

Laser Power

|

1000W~12000W

|

||

|

Max. Loading Weight

|

800kg

|

1000kg

|

1400kg

|

|

Machine Weight

|

3300Kg

|

4000Kg

|

5100Kg

|

|

Overall Dimensions (L*W*H)

|

4850X2730X1700mm

|

6015X2730X1700mm

|

6015X3300X1700mm

|

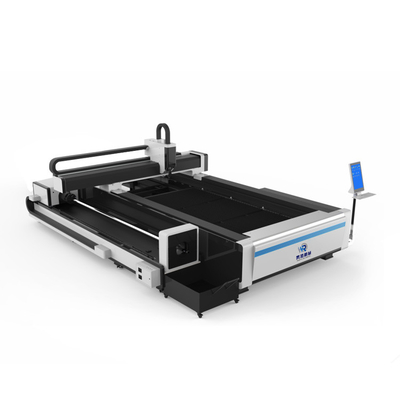

1.Bed part The bed body is completely independently researched and developed. The bed base is welded by a square tube and processed by a large gantry milling machine. We have many years of processing experience for large-scale machine bed, high temperature annealing to eliminate stress and natural failure treatment, internal After the partial stress is released, finish machining is performed to ensure machining accuracy! The parallelism of each machine bed out of the factory is less than 0.02mm. Only with a solid bed can an efficient and high- precision cutting speed be guaranteed!

Features and advantages: ① The machine base is thick and stable, stable and reliable under high acceleration; ② Use multi-channel bottom automatic partition dust removal, so that there is nowhere to hide the smoke and dust; ③ Automatic lubrication and refueling, uniform and consistent refueling, eliminating the trouble of manual refueling; There is a waste car at the bottom of the cutting area, which can be pulled out regularly to clean up the waste;

1. Outside package: Standard marine export plywood case.

package according to your requests. Delivery Detail: Shipped in 15-30 working days after payment.

Honest laser main products cover the full power of fiber laser cutting, laser machining equipment and cutting equipment, products widely used in iron and steel metallurgy, non-ferrous metal, automobile and parts, aviation, military electronics, precision instruments, machinery manufacturing, hardware tools, integrated circuit, solar energy, etc.

The company advocates "taking the interests and needs of customers as the foundation", and devotes itself to "creating value for customers and benefits for society".

Advanced technology is the guarantee of product quality, the company has completely independent intellectual property rights, has established a sound and effective quality management system and internal control system;

The company's products and services to prevention, the implementation of customer return visit, continuous improvement, quick response, efficient and accurate service mechanism, to ensure the stable and efficient operation of products, maximize to help customers to improve economic benefits.

The sales area covers the whole country, and expands to overseas, and the products are highly praised by customers.

The company is willing to work together with all partners to make progress and win-win development together to create the largest high power laser processing equipment manufacturing and research and development base.